1. All metal parts on the lightning rod must be galvanized, and the galvanized layer shall be protected during operation.

2. The needle tip shall be made of galvanized steel pipe, the thickness of the pipe wall shall not be less than 3mm, and the tin brushing length of the needle tip shall not be less than 70mm

3. When installing the lightning rod, it shall be installed firmly vertically, and the allowable deviation of perpendicularity is 3 / 1000.

4. Welding requirements: lap welding shall be adopted, and its lap length must be in accordance with relevant regulations.

5. Flat steel is twice its width (and at least 3 edges are welded).

6. Round steel is 6 times its diameter.

7. When the round steel is connected with the flat steel, its length is 6 times of the diameter of the round steel.

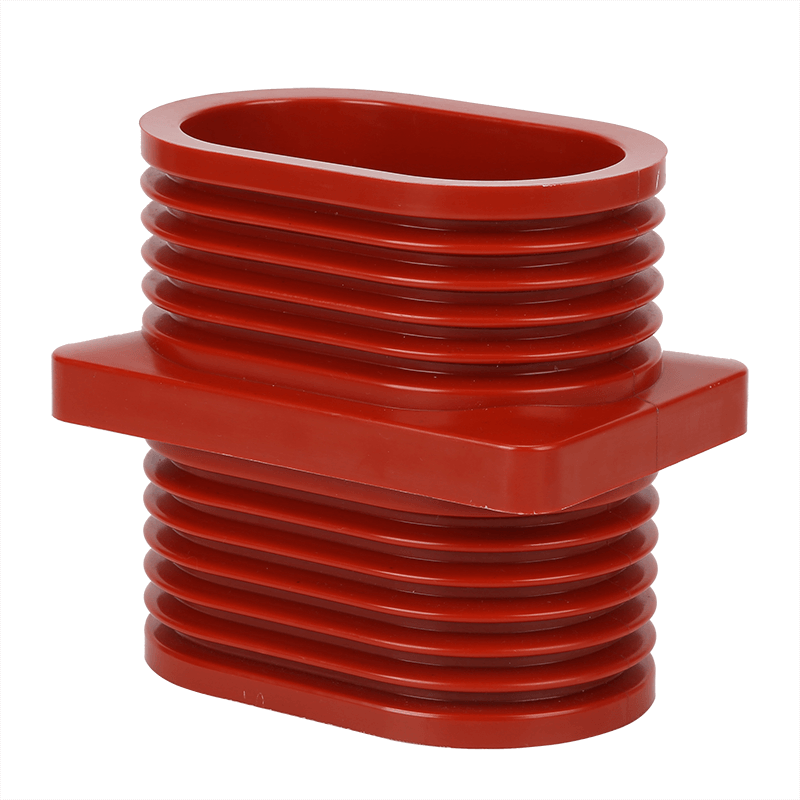

8. The lightning rod is generally made of round steel or steel pipe, and its diameter shall not be less than the following values:

1) The independent lightning rod generally adopts the galvanized round steel with a diameter of 19mm.

2) The lightning rod on the roof adopts 25mm diameter galvanized steel pipe.

3) The lightning rod at the top of the water tower shall be galvanized steel pipe with a diameter of 25mm or 40mm.

4) The lightning rod on the chimney top shall be 25mm diameter galvanized round steel or 40mm diameter galvanized steel pipe, and the lightning ring shall be 12mm diameter galvanized round steel or 100mm2 galvanized flat steel with a thickness of 4mm.

Precautions for fabrication and installation of lightning rod

The height of lightning rod is generally 400mm or 500mm.

1. When making lightning rod, the welding part is not full, the welding flux is not treated cleanly, and the antirust paint is omitted.

Solution: repair welding in time, knock off the coating and apply antirust paint.

2. The body of lightning rod is bent, and the installation perpendicularity exceeds the allowable deviation.

Solution: straighten the needle body again and install it after meeting the requirements.

3. The protection distance between the independent lightning rod and its grounding device and the entrance and exit of roads or buildings does not meet the installation regulations.

Solution: the distance is required to be greater than 3m. When it is less than 3m, pressure equalizing measures shall be taken in time or pebble or asphalt ground shall be paved.

Leave a Reply

Your email address will not be published. Required fields are marked *